Van Hoorn Carbide

The Best Solution

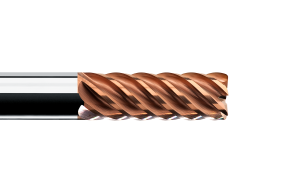

Van Hoorn Carbide end mills are specially designed for your specific applications. The end mills are being produced on the most advanced machines in the market with the best European carbides. Because we offer extreme narrow tolerances for our Van Hoorn Carbide end mills you can work extremely accurate and save a lot on finishing.

The end mills are equipped with specifically tailored geometries and coatings designed to give you the optimum standard solution. All cutters are subjected to a visual inspection. This enables us to guarantee you the best possible quality.

In short, the perfect tool for every application!

Can’t find your tool in our standard program? Click here to order a special.

Click here to view all our end mills.

PARA Tooling

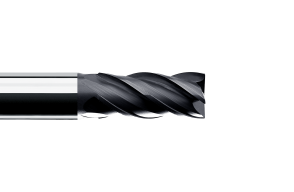

General applications

These carbide end mills are also produced in our high-tech production facility at our headquarters in Weert. There are manufactured from standard carbides and then given standard coatings. Their geometries are derived from the older generation Van Hoorn Carbide end mills and therefore still very useful! These end mills are inspected visually by sampling. Because the costs of developing PARA Tooling end mills are lower, we can offer you these at very competitive pricing.

Perfect for smaller production companies and general applications.

Click here for all our PARA Tooling end mills.

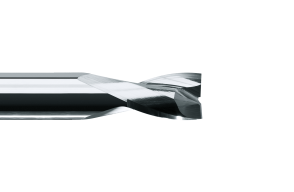

Popular Innovations

-

HAMFXL 6 120 150 12 03 050

12 x 12 x 150 -

VHRS 4 080 064 08 03 100

8 x 8 x 64 -

VHRS 5 120 102 12 03 010 L

12 x 12 x 102 -

VHDB 2 120 107 L60

12 x 12 x 107 -

VHLA 2 030 064 03 15

3 x 3 x 64 -

VHAE 1 005 038 03 10

0,5 x 3 x 38